スマートドール コーテックス

組み立て方法

スマートドールコーテックスの組み立て方法はこちらですが、ご検討する前に必ず下の記事を全て読んでくださいね。

こんにちは!

スマートドールのクリエイター、ダニー・チューです。今日はコーテックスの諸々を説明したいと思います。

2014年6月にスマートドールを発売して間もない頃、僕は、将来的にはソフビ製作がネックとなり、結果的には自分たちの事業の今後を脅かすことになるだろうと考えた。ソフビ製作には手間がかかり、これは費用面だけではなく、労働力の面でも大きな負担となっていた。

スタートアップの時点では、僕たちは、射出成形金型に比べると格段に安価なソフビ金型にしか手を出す資金力がなかった。ソフビ金型 (量産に時間がかかり、1体あたりのコストは高くなる) も数10万円するのだが、射出成形金型 (スピーディーな量産が可能で、1体あたりのコストは低くなる) は数千万円 (それ以上にも) にもなる。

僕は射出成形金型を使ってスマートドールを作れないものか考え始めたのだが、同業者からは、ドールの肌のツヤ消し見た目とソフビの質感をキープしながらこのサイズ (全長60センチ) のドールをプラモデルとして作るのは不可能だとさんざん言われた。既に市場に出ていたたくさんのモデルキットをよく調べてみたものの、僕が求めるツヤ消し感の品質を備えたものは見つからなかった。「大手にもできないことをうちができるわけがない」と思い、このアイディアを断念することに。

2015年のことだった。事業は成長を続け、いずれやって来るこの障壁に関して何らかの策を講じないことには自分たちの事業はこれ以上発展せず、永遠に同じことを繰り返すだけになる、というところまで来た。僕は、このままでは事業の軌道を変えるために打てる手があったのか、そしてまた、もしかすると新しいジャンルの商品を作れたのではないか、それすらわからないまま死んでいくことになるという思いに襲われた。

そこで僕はキャッシュフローのほぼ全てを注ぎ込み、射出成形で作るスマートドールに関して研究開発を始める覚悟を決めた。そして、このプロジェクトをコーテックスと名付けた。「コーテックス」とはラテン語で「外殻」を意味し、解剖学では例えば大脳皮質といったように臓器の最も外側の層を指す。僕たちは、アサフレックスというプラスチックを射出成形したパーツをコーテックスと呼んでいる。

スマートドールのソフビ製パーツも、コーテックスパーツも日本国内で成形しています。金型も日本国内で作っています。ソフビパーツは、液状のソフビを1つの金型に流し込み、オイルバスの中で数分間加熱する「スラッシュ成形」という技法で作られている。オイルバスの中に浸けておく時間が長ければ長いほど、パーツの壁はより厚くなる。そして完成するのが、後々切り取られる湯口 (バリ、フラッシュ) がくっ付いた分割線のないパーツだ。ここでは簡単に説明したが、実際には遠心分離機を使ってパーツを回転させたり、気泡を取り除くために金型を脱泡機に入れたりといったもっとたくさんの工程がある。

コーテックスのパーツは射出成形金型を使って作られる。これは、アサフレックスのペレットがバレルの中で加熱され、その後2つのパーツからなる金型に超高圧で射出されるという仕組みだ。この際に金型を開けようとする力が生じるのだが、450トンの圧力が射出の工程における金型の分解を防いでくれる。しかし、いくら強い圧力をかけたとしても射出成形したパーツには必ず分割線が出てしまう。

コーテックスほど僕の頭を悩ませたものはいまだかつてない。これまで同じようなものをこのサイズで作った人はおらず、それゆえ全てを自分たちで一から考えなければならなかった。3Dの出力物はコンセプトを視覚化するという点では大いに役立ったが、最終的な材料と同じ性質は持たない。金型を作って初めて、材料や形状が特定の状況下でどのように変化するかがわかるのだ。開発に一番時間を要したのはこの工程だ。金型そのものは2017年末には用意できていたのだが、商品を皆さんに販売できるレベルまで引き上げるための修正に1年以上を費やすこととなった。

なかには丸々数か月かかった修正もあり、うまくいかなかった時には心が折れそうになったToT。

でも、そのような困難なくしてはより良い商品を生み出すために必要な知識は得られなかっただろう。

2019年に入り、僕たちはスマートドールの需要の飛躍的な伸びを感じている。現在1か月に成形できるソフビはたった1000体であり、需要に供給が追い付いていない。

しかし、これほど整ったタイミングがあるだろうか。コーテックスと名付けた、射出成形バージョンのスマートドールを生み出すための4年越しのプロジェクトが今、日の目を見ようとしている。コーテックスであれば月間数十万体の成形が可能となる。時計台を救うべく、僕たちは代替のタイムラインを作った。

さっきも言ったように、成形技法を変えることで生産量を増やす方法を見つけることがコーテックスプロジェクトの目的だったのだが、スマートドールのフォルムをこれまでと全く同様に保つことは譲れなかった。僕たちは、ソフビバージョンのスマートドールの既存の骨格と互換性があるようにコーテックスをデザインした。つまり、オプションハンドパーツや胸といったソフビパーツや、全てのアパレル、アクセサリー、ウィッグがコーテックスバージョンにも使えるということだ。ソフビとコーテックスの決定的な違いは材料 (およびその性質) とドールの組み立てられ方だ。

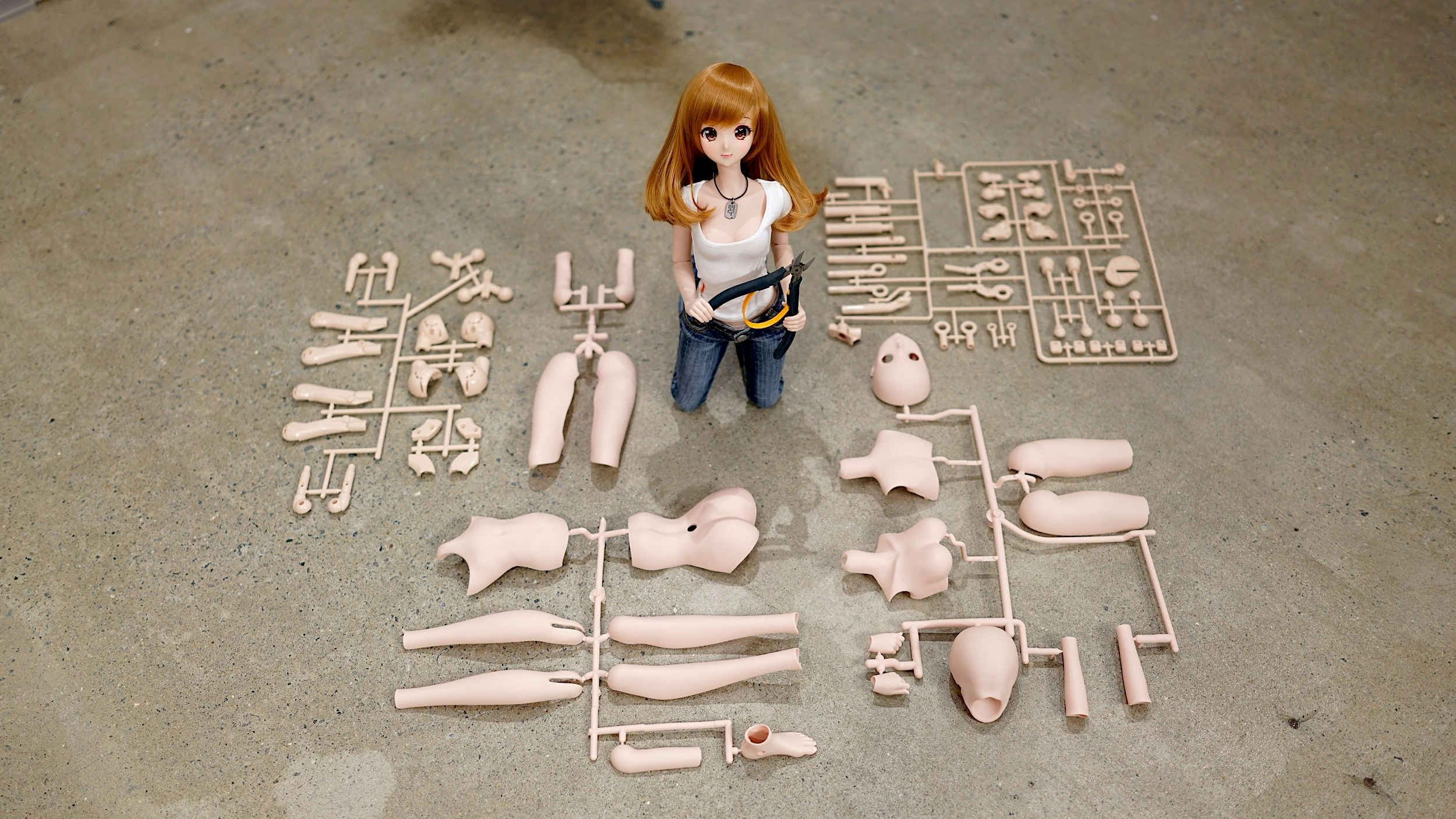

コーテックスの開発を進めていた時、僕はその進捗状況をソーシャルメディア上でシェアしていたのだが、多くのファンが自分の手でスマートドールを組み立てたいと思っていることを知った。これは素晴らしいことだ!もしファンが自分でスマートドールを組み立てられるとすれば僕たちはその作業から解放されるわけで、浮いたコストをユーザーに還元できるのだから。

しかし、コーテックスはガンプラやフレームアームズ・ガール、モデロイドのプラモデルのようにユーザーが自分で組み立てられるようにはデザインされていない。僕たちスタッフが組み立てることを前提にデザインされたのだ。ソフビバージョンと同様、表面をペーパーがけしたり、バリ取りをしたりといった、シェルとなるパーツの仕上げ作業がたくさんあるのだ。骨格に関しても特殊道具が必要で、グリスの塗布、バリ取り、トルクの調整といった作業もある。実は骨格 (ミライフレームとしてお馴染み) はスタッフ採用試験の一部なのだ。「ミライフレームチャレンジ」では、ミライフレームを1時間以内に作れる人をその場で採用している。スマートドールの製作チームの全員がこのチャレンジをこなしてきたのだ。

プラモデルのユーザーは、これほどの労力あるいは技術を要するモデルを自ら組み立てようとは思っていない。でも、ユーザーが一から自らの手で組み立てられるスマートドールをデザインするとなれば、僕たちはユーザーの期待に応え、構造の耐久性を犠牲にしなければならない。アパレルを着せたスマートドールの重さは1キロになることも。内側の骨格と外側の構造は頑丈で、ドール自体の重みに耐えられるものでなければならない。

僕も最終的にはコーテックスをキットとして発売したいと考えているが、その前にクリアしなければならないことがある。

コーテックスは、工業デザイナーのレイモンド・ローウィーによって提唱されたMAYA原則 (先進的ではあるが、まだ受け入れられる) にしたがって段階的にローンチされる予定だ。MAYA原則は、消費者は目新しいものを求めるものの (新しいもの好き)、先進的過ぎるコンセプトに直面するとそのアイディアに対して否定的になる (新しいもの嫌い) としている。未来を見据えてデザインしながらも、消費者にはその未来を段階的に届けるというのがソリューションだ。

最初のステップは、当初の予定通り、コーテックスを組み立て済みスマートドールとして発売することだ。コーテックスバージョンが市場で受け入れられたところで、コーテックスキットを投入する。さっきも言ったように骨格の組み立てには特殊工具が必要となるのだが、僕たちはそういった道具を必要としない新たなパーツを開発中である。ただ、この新しいパーツは年末まで完成しない。初めて発売されるコーテックスキットは「Cortex Ninja Grade」(CNG) と呼ばれるもので、骨格は既に組み立てられた状態で出荷される。そして今年後半、スマートドールのフレームも、シェルもユーザーが自ら組み立てる「Cortex Final Boss Grade」(CFBG) を発売する予定だ。これはスマートドールの最廉価バージョンとなる。

CFBGをパーフェクトで作れる方に仕事依頼したいもしくは採用したいので連絡します!

スマートドールランドの用語集

さらに先へと進む前に、ここスマートドール界で飛び交う用語についておさらいしておこう。

シェル (SHELL) - スマートドールの外皮。

コーテックス - 射出成形した外皮パーツ。

ソフビ - スラッシュ成形した外皮パーツ。

骨格 (フレーム) - スマートドールの内側の骨格。

ソフビバージョンのスマートドール - 頭からつま先までソフビでできたスマートドール。2014年以来僕たちが作ってきたもの。出荷前に僕たちの手によって組み立てられる。

コーテックス・コンプリート - 体全体と頭がコーテックスでできたスマートドール。出荷前に僕たちの手によって組み立てられる。

コーテックス・ハイブリッド - 頭はソフビ、体はコーテックスでできたものを指す言葉。僕たちの手によって組み立てられる。

コーテックス・ハイブリッドのなかには手と胸がソフビのものがあるが、その場合は商品説明にその旨明記される。

Cortex Ninja Grade (CNG) – 骨格は完全に組み立てられた状態で出荷されるがシェルはユーザーが自分で組み立てる、コーテックスのキット。

Cortex Final Boss Grade (CFBG) – 骨格もシェルもユーザー自らが組み立てるコーテックスのキット。

最も高価なものを先頭に、様々なスマートドールの商品を下記の通りにリストアップしてみた。

[最も高い]

ライセンス製品のコーテックス・ハイブリッドのスマートドール

ソフビバージョンのスマートドール

コーテックス・ハイブリッドのスマートドール

コーテックス・コンプリートのスマートドール

Cortex Ninja Gradeのスマートドール

Cortex Final Boss Gradeのスマートドール

[もっとも安い]

ライセンス製品のスマートドールについて

ライセンス製品のスマートドールの女の子たちは全てコーテックス・ハイブリッドとなる。生産量の大幅な増加が期待できるため、浮いたコストをその版権キャラクターのアパレルやアクセサリーに投入できる。

現在のタイムラインではより多くのスマートドールの製作が可能で、これはつまりより多くのライセンス製品を意味する。ただし、外皮のバリ切りする時間が短縮されたとはいえ、まだ人間の手で仕上げを行い、ボディーを組み立てて接着する必要があることから、実のところ人件費は大きく変わらない。

版権料はアニメ、ゲーム、ハリウッドスタジオごとに異なる。3パーセントから33パーセントといった販売価格の一定のパーセンテージを要求する形態のものもあれば、MG (ミニマムギャランティ)の「最低保証」と呼ばれる形態のものもある。これは端的に言うと「まずはこの金額をいただきます。話はそれからです」というものだ (笑)。このMGの相場は契約の相手によって100万円から1000万円と幅がある。このようなコストが価格に反映されることから、ライセンス製品はうちのオリジナルキャラクターよりもかなり高くなるのだ。

期待の設定

2014年6月にスマートドールを発表して以来、僕たちは自分たちの商品がどのようなもので、逆にどのようなものではないのか、期待を設定することを常に心がけてきた。「期待を設定する」を聞くとピンと来ない方はほとんどですが、例えばお客さんが何かを買う前に商品やサービスに対する期待はあるかと思う。しかし、期待していた仕様と違うものを買ってしまうと「あれれ?」となりますよね?この状態は「期待の不一致」と言います。

僕たちにとって最も大切なことは、たとえお客様がスマートドール以外のブランドを選ぶことになったとしても、お客様が購入の決断をするにあたり、皆さんに十分な情報を提供することだ。言うなれば、ピーナッツアレルギーがあると知っているお客様にピーナッツを売りつけていては強いブランドは築けない。短期的には儲けられるかもしれないけど、長期的に見れば自ら墓穴を掘っているようなものだ。でも私たちはこれから長きにわたってここで勝負をしていくわけで、そんな下手は打たない。

スマートドールは「侘び寂び」をデザイン原理としている。不完全性も適切な量が集まり、相互補完すれば美しさが産まれる、というのが「侘び寂び」の概念です。

僕たちがドールを手作りしている上で自然と生じる湯ジワ、凹み、ヒケ、黒子などの現象は全てのスマートドール本体に所々で現れます。これらの現象を「欠陥」と捉える方はなるべく期待の不一致にならないようにしたい。

スマートドールは手作りによる商品で、スカイネットが自我に目覚めるその日まで、人間の手で作り続けます。ターミネーターが作る完全無欠の商品をお求めの方は、他のブランドをあたってみてはいかがだろうか。

次の項目「コーテックスそれともソフビ?」では、コーテックスとソフビの長所と短所をまとめた。期待の不一致にならないように是非読んで欲しい。

コーテックスそれともソフビ?

コーテックスについて既に誤解が生じているようなので、この誤解を解消しておきたい。コーテックスがスマートドールの単なる廉価版というわけではない。ここでもう1度おさらいしておきたい。コーテックスのパーツは安価なものの、金型はとても高価だ。ソフビのパーツは高価なものの、金型は安価だ。

コーテックスが単に「分割線のあるソフビバージョン」というわけでもない。ソフビバージョンとは材料も性質も異なる。コーテックスとソフビに優劣をつけられるわけでもない。ユーザーが何を求めているのかによって、コーテックスにもソフビにも短所も長所もある。より良く理解するために、スマートドールのソフビバージョンとコーテックスバージョンを比べてみよう。

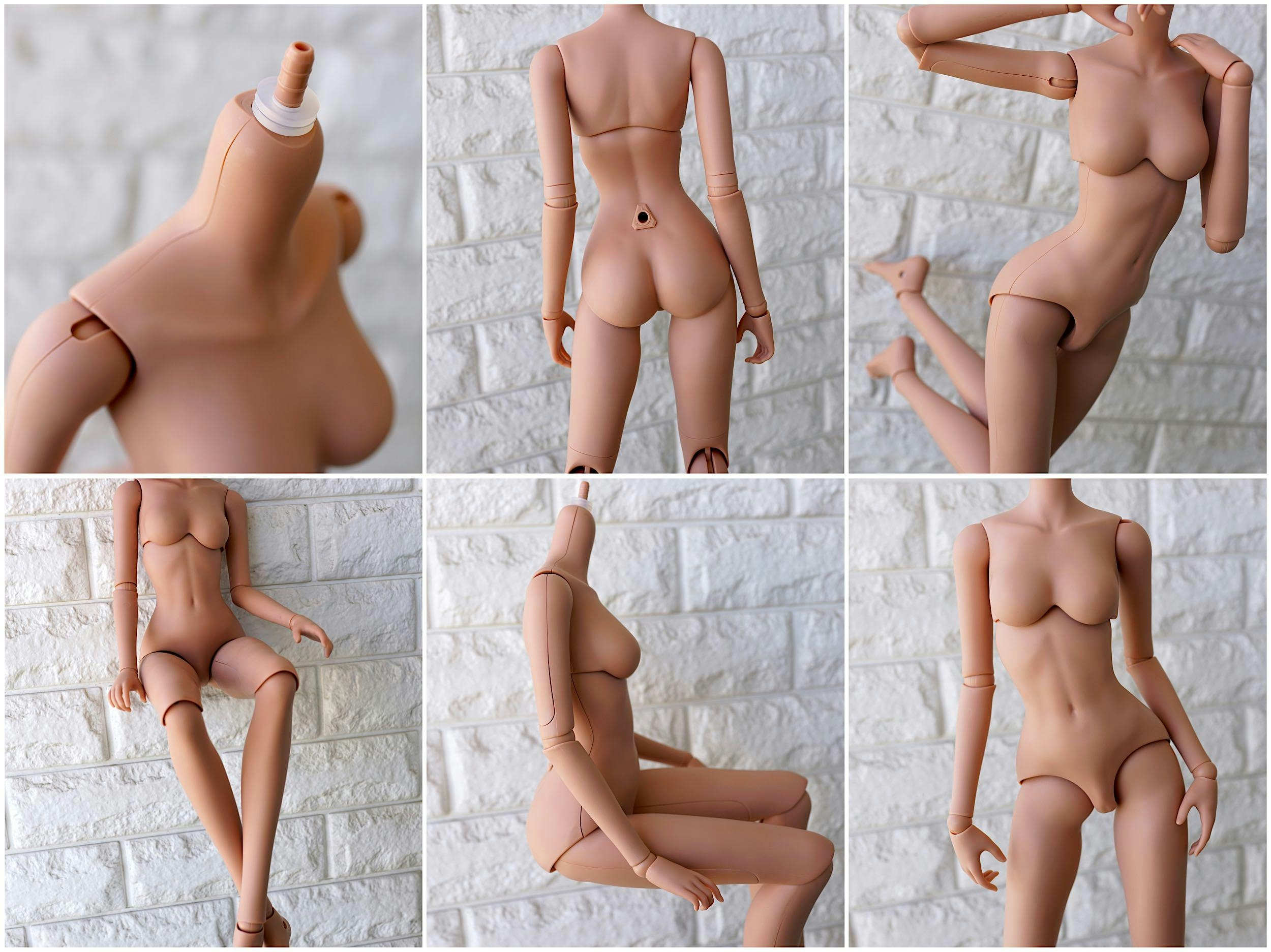

コーテックスのパーツにはソフビのパーツにはない分割線がある。コーテックスのパーツは固く頑丈だ。射出成形ではシェルの内側までデザインできるようになったおかげで、フレームにシェルをひっかけられるようになった。おかげでボディーの作りがこれまでよりもしっかりとしたように感じられるはずだ。一方のスラッシュ成形では手を加えられるのはソフビの外皮の外側だけであり、外皮は内部の骨格にひっかけるのではなく、ただ骨格を覆っているだけだ。ソフビバージョンが若干グラグラしているように感じられるのはこれが原因だ。

コーテックスのパーツの合わせ目には隙間が出ることも。例えば胴体の左側の合わせ目は隙間がなく、右側には隙間が出ていることも。

コーテックスパーツのアンダーカット形状により、金型から突き出される際、パーツがデコボコした形状になることも。

ソフビバージョンもコーテックスバージョンも布や爪などで表面がこすられるとすり傷ができる。すり傷はソフビバージョンではココア色、コーテックスバージョンでは全ての肌色でより目立つ。すり傷は1500番の紙やすりで簡単に消すことができる。

うっかりスマートドールを落とすと、絶叫と共にスマートドールの頭が360度回転し始めます。落とした床の表面によっては、ドライヤーで温めることでソフビの外皮に生じた凹みは取り除くことが出来る。しかし、あなたがパテで傷を埋め、ペイントを施す前に紙やすりをかけて滑らかにするといったプラモデラーでない限り、コーテックスについた凹みや深い傷を消すのは難しい。

コーテックスはソフビに比べて生地の色移りに強い。コーテックスについたほとんどの色移りはシンナーで落とすことができるが、ソフビについた色移りはなかなか落ちない。

ガンプラを作ってきたような経験がある人は、改造したり塗装できる材料特性を備えたコーテックスを好むだろう。

スマートドールにはアパレルを着せておきたい人は、可能であればコーテックスを選ぶべきだ。わざわざ袖やパンツの裾をめくって分割線を探さない限り、ソフビバージョンとの違いには気付かないはずだ。スマートドールに色移り恐れのある服を着せるのが好きな人もコーテックスを選ぶと良い。シンナーさえあればほとんどの色移りを落とせる。

ソフビは柔らかくてムニュムニュしていることから、スマートドールにより幅広い動きをさせられるのはソフビバージョンだろう。例えばソフビの胸は柔らかいことから、首を横に曲げることができる。コーテックスではできないことだ。ただし、両者には互換性を持たせていることから、コーテックスの胸とソフビの胸を取り換えることが可能だ。ソフビのほうがムニュムニュしていることから、ソフビバージョンのほうがコーテックスバージョンよりも膝を若干さらに後ろへと折り曲げることができる。

前述の通り、コーテックスは肌の色を問わずすり傷が目立ちやすい。こうしたすり傷を消すには、コーテックスバージョンに付属している紙やすりを使うと良い。力を入れず、表面を軽く撫でるだけでよい。修復しようのない深い傷がつくことから、アパレルやブーツについたジッパーには注意が必要だ。色移り防止レギンスや靴下を使ってほしい。

組み立て済みのコーテックスバージョンのスマートドールのシェルは接着されている。何らかの理由によって脛や肩のシェルを交換したい場合は、シェルを自分で壊す必要がある。一方、ソフビであれば熱を加えることで外皮を簡単に交換できる。

柔らかいソフビは熱を加えることで元の形状に戻る (大抵の場合は) 形状記憶ポリマーだが、コーテックスは変形することがあり、いったん変形すると元には戻らない。

コーテックスとわび・さび

射出成形金型はまずはCNC (コンピューター数値制御) による機械加工で作られ、その後、人間の手によって磨かれる。この工程があることで表面に有機物ならではのでこぼこができる。ソフビと同様、僕たちが出荷するスマートドールの全てに成形の段階でランダムに傷 (黒子、湯ジワ、不均等の表面) がつけられる。みんな同じように見えるスマートドールだが、一体として同じものはないのだ。

コーテックスバージョンの頭に関して言えば、ソフビバージョンの頭と同じ形、そして表面の凸凹をキープしたかったことから、ソフビバージョンの頭のCT (コンピューター断層撮影) をとり、そのデータをもとに射出成形金型を作った。

スマートドールをご購入される前に必ずうちのデザイン思想を読んでください。

コーテックスに関するQ & A

最もよくいただいている質問は「なになにちゃんのコーテックスバージョンはいつ発売されますか?」と「キットはいつ発売されますか?」だ。

2019/??/?? コーテックス・コンプリートの発売 (みらいアニバーサリー、ガイア) のソフトローンチ (ごく限られた数量のみ)

2019/05/20 コーテックス・ハイブリッド 城ヶ崎美嘉の予約開始

2019/05/31 コーテックス・ハイブリッド 城ヶ崎美嘉の出荷開始

2019/??/?? コーテックス・コンプリート (みらいアニバーサリー、ガイア、メロディー) のオフィシャルローンチ + 出荷

これが現時点でのスケジュールだが品質優先で変更になることも。もしご要望のものがここにない場合はもうしばらく待って欲しい。

コーテックスと今後

コーテックスの登場によって僕たちにとって全てのなにもかもが変わるほか、僕はそれが「大型ファッションドールのプラモデル」という新たな市場の誕生に繋がると確信している。最終的には僕はライセンス製品のスマートドールもコーテックスキットとして発売して、浮いたコストを皆さんに還元できるようにしたいと思っている。

しばらくの間はソフビバージョンのドールの製作を続けていく予定だが、コーテックスの進化は、僕たちが現時点では気付いてもいない新たなタイムラインを今後も生み出していくことだろう。スマートドールに関して言えば、未来は皆さんの手の中にあるのだ。

ミライストア

東京の五反田にあるスマートドールの旗艦店ミライストアではコーテックスの女の子たちは展示されています。近日ミライストアでご購入することも。