Meet Team SmartDoll

Hey folks! Danny Choo here. Today I would like to talk about our company culture and introduce some of the team who make your Smart Doll goodies.

The quality of our products is what we want to be known for so to achieve this we need to be customer-centric. However, to be truly customer-centric we need to be unconventional and build our business around employees - not customers.

Focusing on employee welfare and the working environment contributes to creativity in producing a high-quality product and service which is what we want for ourselves and what our customers seek.

For this reason, we do not follow certain retail "rules" of treating the customer like god (as taught in Japan) nor do we practice "the customer is always right" - as taught in the West. As you know, consumers want things yesterday at prices that they deem "reasonable" but to achieve this we would need to force staff members to work longer hours for less wages, reduce quality of workmanship (throw it together), use cheaper materials and force vendors to lower unit costs. We could just adopt the tried and tested fast fashion model - but I'm unwilling to do any of this as we will discuss ;-)

Let's imagine the 24 hour day as a pie and then let's divide that into 3 slices - each representing 8 hours. 1 slice for sleep, 1 slice for work and the remaining slice ideally for play but ends up being divided up between commuting, hygiene (shower, laundry), preparing and having dinner (then washing up) and let's not forget the 1 hour it takes to get out of the house (what's up with that?) which only leaves a couple of hours for what I call "personal development" - time set aside to learn new things so that when life throws the worst then you can be prepared.

It's important that our team members get their own personal development time no matter how busy it gets at work. If we force folks to work longer hours then it means less sleep or personal time.

For this reason, since we launched in June 2014, we have never ever asked any of our team members to stay behind to work late to meet the demands of customers - even if it could mean potential loss of sales.

Some folks understandably expect perfect machine-made products that all look the same - unfortunately, because our Terminator models (robots that can make stuff look exactly the same) were all sent to the past and then destroyed by some "Connor" - we continue to ask our talented team of humans to handcraft each and every Smart Doll. Making a Smart Doll involves many teams spread across Japan from the folks who do the injection molding for the frame in Shinjo Yamagata, slush casting in Katsushika Tokyo to body assembly in Gotanda Tokyo.

We do not rush or cut corners in production no matter how many consumers continue to demand "when are you going to release that doll you promised us blah moons ago?!" - even if that means the consumer gets fed up waiting and ends up buying other brands. We do not release half baked products for the sake of a few extra bucks.

If you follow business news you will most likely have seen some CEO saying "our goal for this quarter is to make X million USD" or "we want to have 50 stores across America by the end of this year."

Money is important to continue operating but we never set monetary targets - instead we have goals like "next month we plan to release 4 new cuties." However, quality comes first so if we don't manage to release the 4 cuties then that's fine - we would rather release 3 quality products than 4 with questionable quality. This is just one of the reasons why we do not advertise a release schedule.

Inventory management takes up a large portion of running the business and involves many factors such as logistics, storage space, safety (of products and employees), environmental controls such as temperature, humidity, and pest control.

We want to focus on product development rather than counting and managing inventory - for this reason, some of our products are only available for a limited period. Some consumers choose to call this "greedy" through what they explain as "only targeting folks who have readily available cash."

Keeping such a vast amount of inventory for an indefinite period will simply involve longer working hours and cramped working conditions to make space for stock. As inventory management in itself does not generate cash, we would have to lower wages to make sure we still retain margins - this is the real definition of greed but human costs are not a concern for these said consumers who want to be able to buy what they want when they want.

This is the reason why so many suffer in the fast fashion business where humans are forced to work in appalling dangerous environments so that the owner can reduce costs - search for "Rana Plaza factory" to read about how 1,134 people died working in a building that crushed them to death - consumers demand cheap goods > manufacturers threaten factory owner to lower unit costs or they go elsewhere > factory owner reduces wages of workers / cut costs on working conditions.

The toy export industry in Japan played a leading role in the recovery of Japan after the war. In particular, as advances in plastics and vinyl technology progressed, the toy industry saw exceptional growth. However, as toy production gradually shifted to other countries in the region to reduce costs, most toy manufacturing facilities in Japan went bankrupt and only a handful of them are still in operation today.

Smart Doll is heavily influenced by Japanese culture and as such, we feel that it’s important to keep production in Japan. We are fortunate to be able to work with some of the facilities that still cast vinyl the same way they have been doing since the ’60s through a process known as Slush Casting.

Production costs in Japan are much higher than producing elsewhere in the world but we would not have it any other way. We pay vendors the highest rates in the industry to make sure we can both maintain a win x win partnership - if we squeeze our vendors to lower costs which eventually leads to them going bankrupt, we would essentially be shooting ourselves in the foot - but we are in this for the long run and need our feet to do the running ;-)

Speaking of feet, we work with Takashin in Minami-senju Tokyo to craft our Smart Doll shoes in the same way they craft shoes for humans. They also produce shoes for the Japanese brand DIANA which you may have heard of from the Makoto Shinkai anime The Garden Of Words.

Being born and bred in the United Kingdom, I had a dream - the Japanese Dream of living and working in Japan. After moving to Japan over twenty years ago, I first started my career in IT eventually serving as Website Manager at Amazon. I left corporate life to follow my dreams and eventually created Smart Doll. But what about the dreams of my team?

I am under no illusion that our team members will work for us forever - while I would love them to (tears), it's important that they follow their heart to fulfill their dreams too. For this reason, we allow all team members to have their own side businesses - even if clashes with our business of creating fashion doll products.

This is Stella who has a dream of starting up his own business to fabricate prototypes for production. My job is to make sure he can learn the skills he needs on the job so that eventually he can start his own gig - and hopefully have us as a client.

The norm in Japan when looking for a job is to buy a pre-formatted resume from a convenience store, attach a photo of yourself and send it in. As if a photo can really provide any information at all to decide whether to interview a candidate? To work in Smart Doll Land however, no resume or photos are required.

All our team members have figured out two things - how to assemble the Mirai Frame without instructions in an hour - and how to take the test in the first place. One does not simply write in asking to take the test. If you can figure this out then we look forward to working with you ;-)

This is Bobbi from Detroit Michigan who took the test and now is a member of our team working on Smart Doll production and accessory development.

As previously mentioned, the dreams of our team members are important but sometimes they are at a stage in their life where they are not sure which path to take - I know what this feels like as I have been there before. Until they discover that path, I want to continue providing opportunities for team members to learn new skills on the job. This is Alan - a true all-rounder who works on Smart Doll production, 3D modeling and now learning filming and video editing.

Apart from the few licensed products, we do not advertise a product release schedule. The reason is that even if we aim to meet a deadline, there are too many factors outside of our control that can affect product release dates - things like a virus for example. As previously mentioned, much of this can still be alleviated by working longer hours which may get products out on time for the consumer - but take away personal development and family time from our team - this is not going to happen on my watch.

Our retail store Mirai Store Tokyo remains closed since March 2020 as the allure of our cute Smart Dolls would have put customers at risk from getting infected on the way to the store - and perhaps infect our team members too.

Many have expressed disappointment even though most retail stores in Tokyo remain open but we prefer to choose the safety of our team members and Smart Dolls.

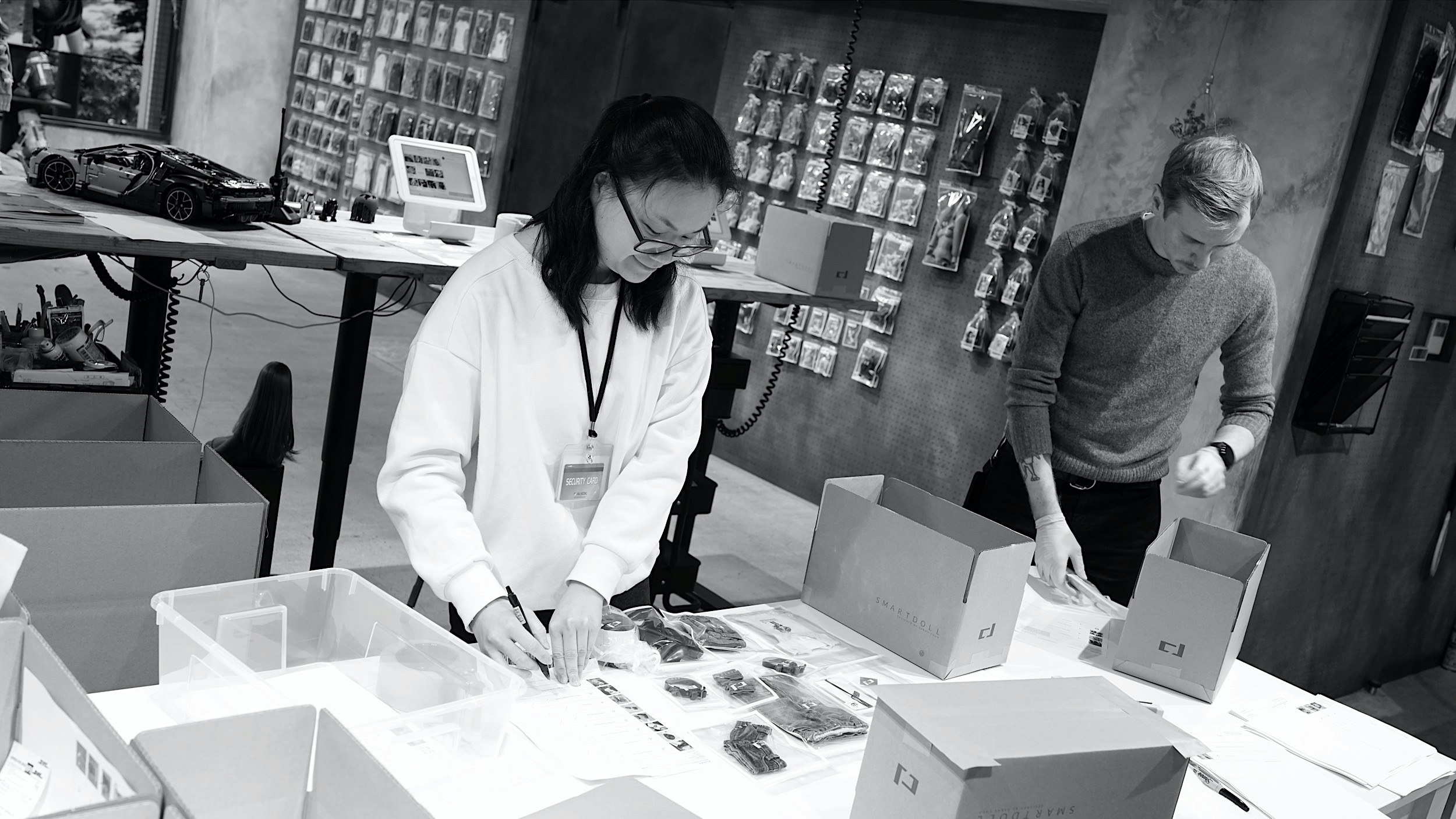

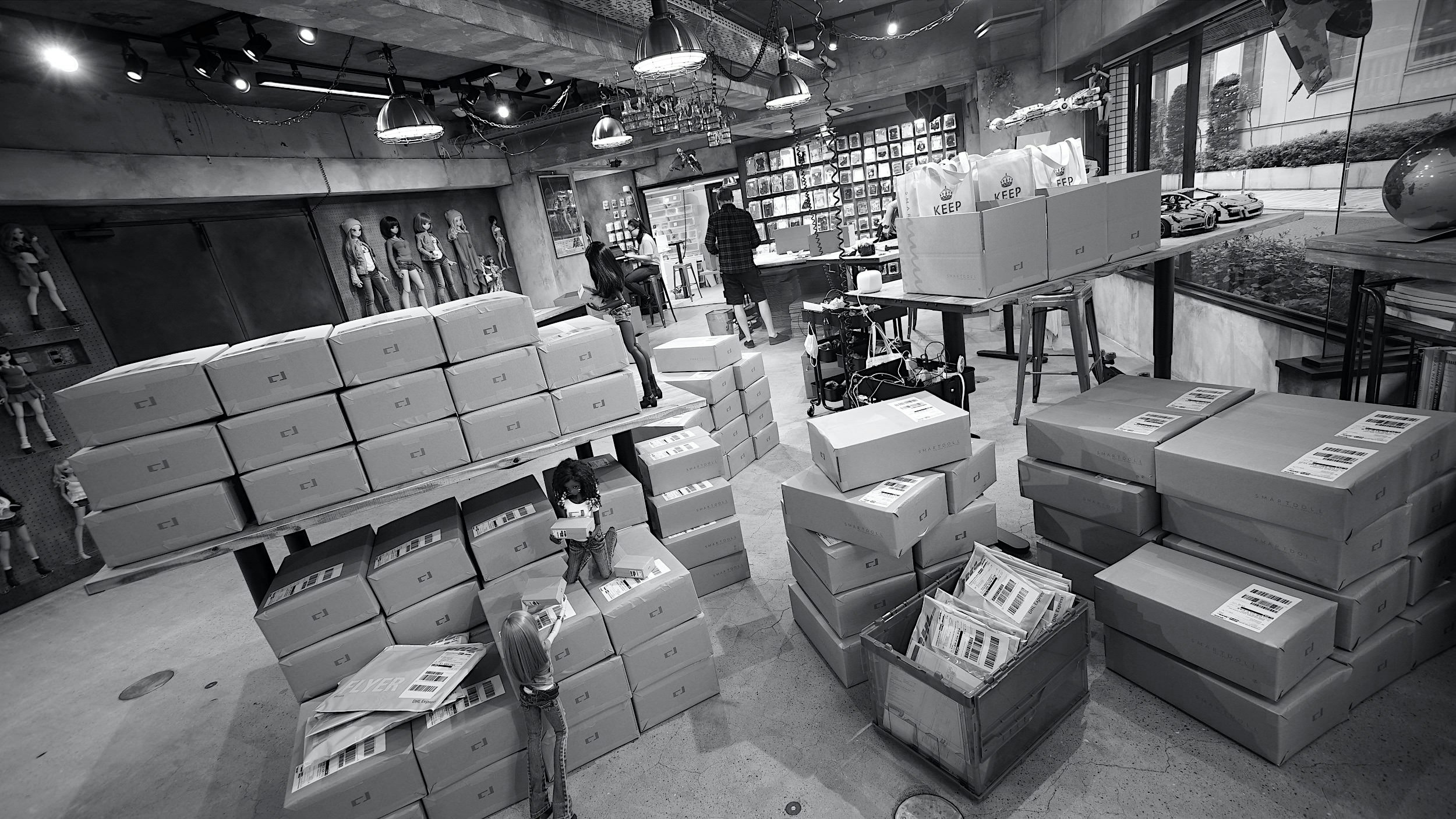

However, while Mirai Store remains closed (and will probably remain so for the rest of 2020) we utilize the space to make picking and packing a more comfortable experience for our team members. Since we entered the post-apocalyptic era, Smart Doll sales have increased exponentially meaning that the extra space for shipping is welcomed.

Having worked in IT for much of my career as a Computer Engineer for Japan Airlines, Website Manager at Amazon and as Product Manager at Microsoft, IT remains a core part of operations. Many companies are accustomed to throwing a human at a problem and then throwing those humans out when not needed. Where possible we use technology to solve problems and automate processes so that humans can be left to do more creative aspects of Smart Doll production.

As we create products, there will always be new production problems which we take a look at and say to ourselves - "there must be a better way to do this." Through this culture of embracing change and not accepting the way things have been done up until now, we have been able to not only invent new tools but analyze and improve workflows that contribute to the accuracy and efficiency of operations.

Go do a Google image search for "customer centric" and you will see a bunch of diagrams that mention things like "customer experience" and "customer value" but very little of them even mention what makes customer-centricity a reality - the employee. From this result alone you can see just how many companies out there place little importance on the needs of the team.

I want our product and brand to serve as an example that we can create a successful business by placing team members at the center instead of customers - and in doing so create products that care about people and the environment.

After reading this you may be under the impression that we don't care about customers but treating them like god is not the right way to go about it. We prefer to treat customers as a friend and partner instead of a celestial being - this is the way it has always been and this is the way it will always be - and most folks seem to be OK with this ;-)